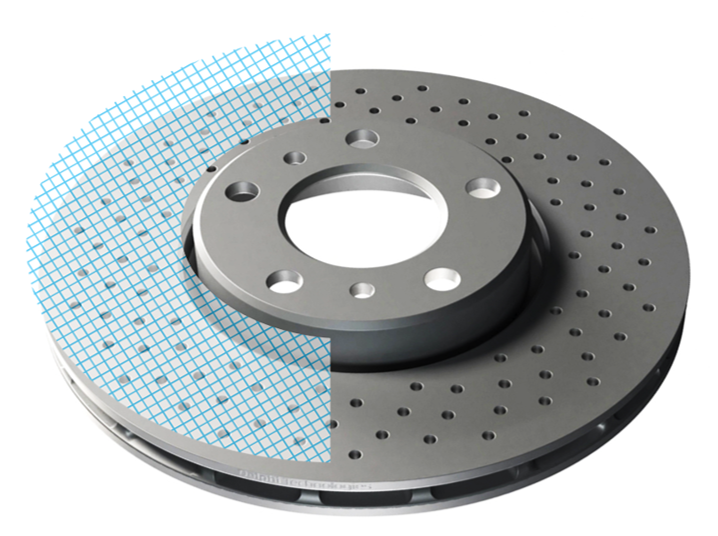

Influence of compounding stainless steel 316 L with nickel alloy IN625 powders during laser powder-directed energy deposition for single layer corrosion protection of low-alloy steel

ALU-V® – Sequential fluid-extraction system for HPDC

Sistema de extracción de gases de moldes de aluminio inyectado. Reduce la porosidad y los defectos de las piezas fabricadas mediante HPDC.

Green industrial scale casting production using engineered molding materials: Sustainable strategies to reduce process gas emissions

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

Get rid of low value finishing operations. Gain efficiency, safe costs.

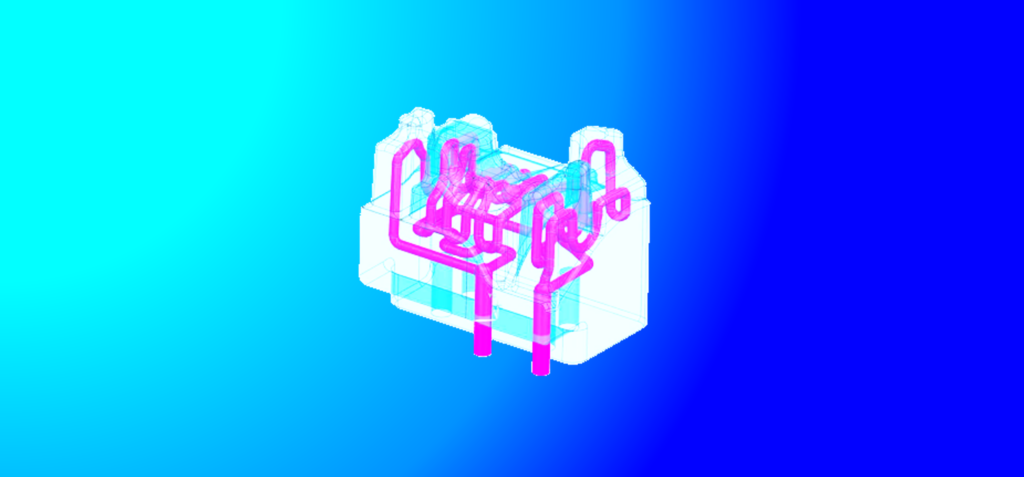

ALU-C® – Ultra-cooling designs

Sistema de extracción de gases de moldes de aluminio inyectado. Reduce la porosidad y los defectos de las piezas fabricadas mediante HPDC.

Manufacturing of Bimetallic Materials with Anticorrosive Properties by L-DED and Hot Forging

ALU-Q® – Molten aluminum quality assessment device

Equipo para la evaluación de la calidad metalúrgica en aleaciones de aluminio. Asegura la calidad del aluminio líquido para fabricar sin defectos.

AUTO-DETACHMENT OF FEEDING SYSTEMS

Get rid of low value finishing operations. Gain efficiency, safe costs.