Green industrial scale casting production using engineered molding materials: Sustainable strategies to reduce process gas emissions

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

Get rid of low value finishing operations. Gain efficiency, safe costs.

AUTO-DETACHMENT OF FEEDING SYSTEMS

Get rid of low value finishing operations. Gain efficiency, safe costs.

Development of sustainable, low-emission “sand-binder” molding systems for casting processes

Characterisation of a cast iron alloy produced with the addition of TiC nanoparticles

Assessment of Harmful Emissions from Multiple Binder Systems in Pilot-Scale Sand Casting

HawkEye: AI-Driven Software for Objective Analysis and Characterization of Nodular Cast Iron Microstructures

KASANDRA® – Software for a real-time prediction of the risk of defect apparition

Simulación predictiva para fundición de hierro. Predicción de la aparición de defectos de contracción en fundición de hierro esferoidal, laminar y grafito compacto.

SMART DOSING SYSTEM – Mg treatment manager

Get rid of low value finishing operations. Gain efficiency, safe costs.

DIGITAL PASSPORT – Access to manufacturing data traceability of castings

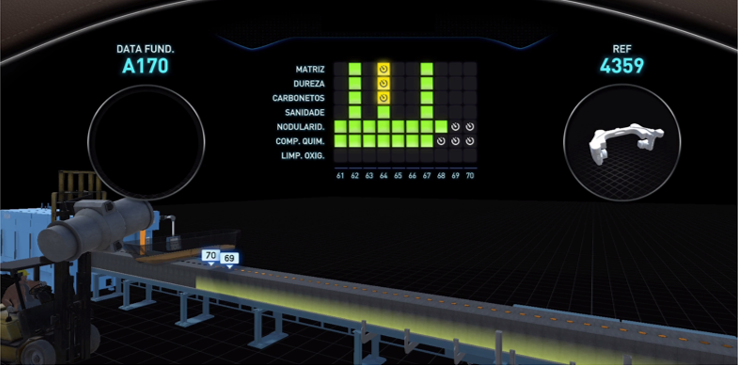

Sistema de control predictivo por inteligencia artificial. Predicción de la calidad del proceso de fabricación de componentes metálicos.