Density change upon solidification of silicon cast irons

Prueba de extracto 1

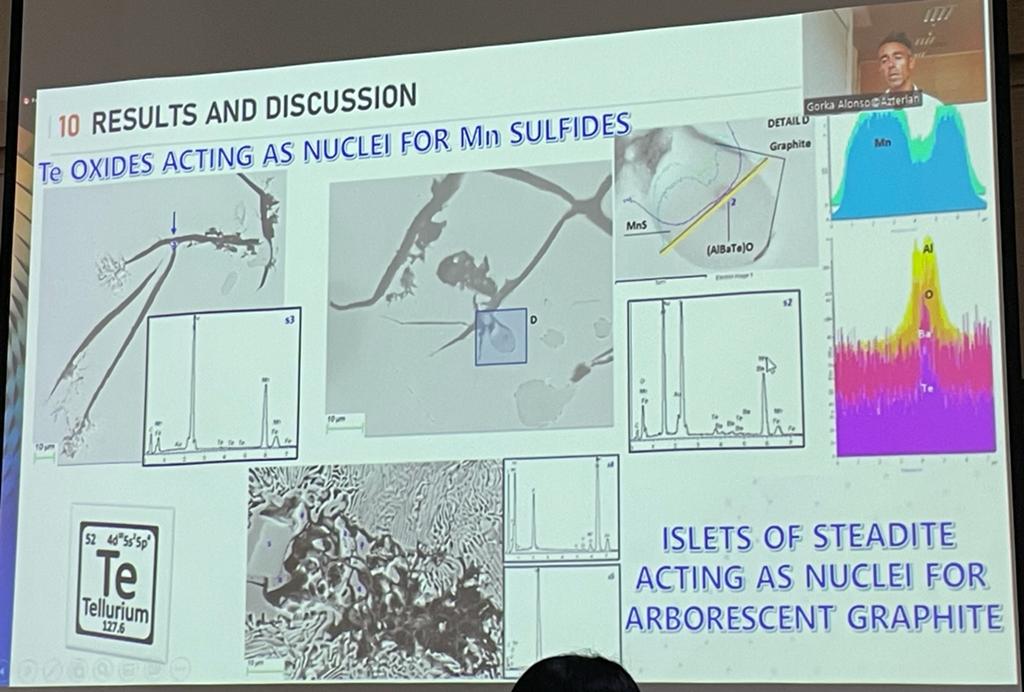

On the crystallography of the Mg–Si–Al nitride nuclei and of the graphite/nitride interface in spheroidal graphite iron

Utilization of steel slag as mold material for green molding castings to minimize silica dust in foundry process

Mechanisms of Formation of Degenerated Graphite in Lamellar Graphite Cast Iron

Optimization of ductile iron casting production by using advanced thermal analysis and simulation techniques

Pseudo-passive films on cast irons: A strategy to mitigate corrosion by acting directly on microstructure

The Effects of Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

Compact graphite iron’s real time manufacturing control by thermal analysis

A new approach of casting simulation tools integrated in the production line

Mechanical properties optimization of as-cast ausferritic ductile iron as a function of section size and holding time

ENGINEERED COOLING® – As-cast ausferritic materials by means of controlled cooling

Get rid of low value finishing operations. Gain efficiency, safe costs.

COLDMOLD – Accelerated cooling of large components

Get rid of low value finishing operations. Gain efficiency, safe costs.