AZTERLAN has developed an innovative solution for conventional and high-vacuum injection molding with a dual function: digitalizing vacuum pressure measurement and applying vacuum inside the cavity to ensure compliance with mechanical and porosity requirements in aluminum components.

The new development joins other technologies developed by the Lightweight Materials team to optimize vacuum in the HPDC process, such as the Alu-V® mold gas extraction system.

With the rise of electric vehicle, injection molding has positioned as a promising manufacturing technology also for developing critical automotive components. However, the main disadvantage of this technology is the inherent porosity of the process, which requires incorporating vacuum systems to manufacture thin walled designs, components with certain safety requirements, and/or parts that belong to welded subassemblies.

However, for greater efficiency of the vacuum process, it is necessary to incorporate a robust monitoring and control system to ensure optimal process conditions. Therefore, digitalizing the vacuum pressure inside the injection mold cavity is an aspect that guarantees whether its application is correct or if there are deficiencies in the process.

In response to this problem, AZTERLAN has developed an innovative solution for intelligent vacuum management in injection molds using a sensor-based device that serves a dual function: digitalizing the vacuum pressure inside the mold and controlling the application of vacuum in the cavity.

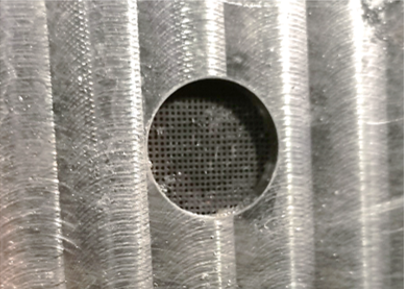

The innovative device combines a pressure sensor located very close to the cavity that monitors the vacuum level during each injection cycle, and can also extract gases from the mold at other locations within the cavity. As researcher Sergio Orden, an expert in HPDC technologies, explains, “The main element of the hybrid solution we have developed consists of a porous sheet manufactured by means of LMD technology that allows gases to evacuate while blocking the infiltration of molten aluminum. At the same time, we have managed to incorporate a vacuum pressure sensor in an area of the mold close to the cavity. By integrating both developments, we have achieved a solution that allows not only to monitor, but also to manage and control the application of vacuum.” This innovative solution is currently undergoing patent processing.

The management and optimization of vacuum in the injection molding process to manufacture low-porosity components is one of the strategic lines of development of AZTERLAN’s Lightweight Materials research team. “Reducing porosity is key to ensuring the mechanical properties and weldability of aluminum components, as well as the first step toward promoting the manufacture of larger components that can perform structural functions”.

Image of the porous sheet in the mold to control vacuum management developed by AZTERLAN.

Manufacturing of the battery box for the electric vehicle by means of die-cast aluminum

This innovative development is the result of AZTERLAN’s participation in the “Future Fast Forward” (F3) project, in which the Light Materials team focused on developing aluminum injection technology targeted at the manufacture a lighter battery box. “The battery box houses the battery cells, the battery management system, and the cooling system, and is the mechanical structure that protects and supports this entire assembly. These component’s main characteristic is their ability to dissipate heat with complex lattice designs and very thin thicknesses. Ensuring the soundness and weldability of this component is essential to ensure the safety of both the vehicle and its passengers.”