Iron Foundry Software

HawkEye. AI-based metallographic analysis software

Aseguramiento de la calidad metalúrgica del metal líquido.

Herramienta de análisis térmico para el aseguramiento de la calidad de la fundición de hierro de grafito esferoidal, grafito laminar y grafito compacto.

Automation, machine vision, and AI for a more efficient and enhanced quality control.

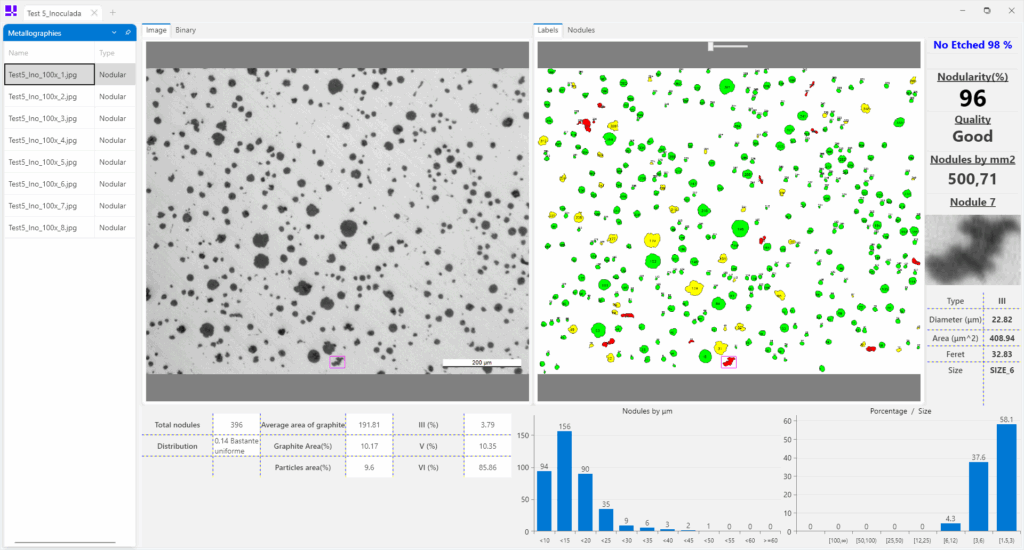

HawkEye ductile iron metallographic analysis software, developed by AZTERLAN, offers industrial foundry companies and testing laboratories the security and agility they need to perform this critical analysis to ensure and validate the properties of castings.

HawkEye combines advanced vision and Artificial Intelligence to automate the analysis of cast iron micrographic images, surpassing the benefits provided by quantitative analysis tools and eliminating the subjectivity and variability inherent in conventional human-led visual inspection.

Thanks to advanced vision, HawkEye quickly and reliably detects the formal characteristics of graphite and the different phases present in microscopic images. By means of Artificial Intelligence, the system interprets and classifies the different elements (in-line with applicable international standards, such UNE-EN ISO 945) and offers a final evaluation of the sample.

HawkEye is compatible with other metallurgical quality control tools (such as the Thermolan® system) to ensure the optimal management of the metal.

Related contents

Quality control software for industrial production of nodular cast iron

Ensure the reliability of your metallographic inspection

- AI-based analysis without the need for technical personnel, whose role is focused on sample preparation and metallographic imaging

- Metallographic evaluation according to UNE-EN ISO 945-1, 945-2, and 945-4

- Analysis of key aspects that affect the mechanical properties and performance of the material: ferrite/pearlite matrix, graphite morphology, nodularity index, presence of carbides

- Designed for the automatic generation of test reports

- Suitable for industrial production and testing laboratories

- Applicable to samples chemically etched and non-etched with Nital 5

- Reduced image processing efforts

- 99% accuracy in nodule classification compared to analyses performed by expert personnel

- Friendly and easy-to-use interface for technical personnel

- Compatibility of the extracted results with other metallurgical quality control software tartegeted at an improved metal management

HawkEye, the keys

Training based on expert knowledge

HawkEye’s development is based on the experience of AZTERLAN’s technical personnel specializing in metallographic analysis and defect diagnosis, who have participated in the validation of the analysis results. Furthermore, the tool has been trained with reports and analyses performed by the AZTERLAN team over time, as well as with metallurgical technical knowledge and regulations applicable to this test.

AZTERLAN has more than 40 years of experience in the development of metallographic characterization and evaluation projects, as well as in the study and diagnosis of defects and failures in service.

Process Optimization

HawkEye stores analysis results in a dedicated database that allows correlation of the results obtained with other production process variables.

This functionality, in addition to contributing to the defect diagnosis process, enables the creation of high-value data sets for machine learning and artificial intelligence models.

The results provided by HawkEye are compatible with other related metallurgical quality control software and tools for improved metal management.

Designed for reporting

HawkEye provides all the necessary data for reporting:

- Sample identification: ID, extraction location, number of samples, and areas evaluated

- Analysis data: image magnification, application standards

- Graphite characterization: morphology, distribution, size

- Matrix characterization: ferrite, pearlite, carbides

Reports can be customized and configured with other relevant data such as graphite nodule count, material designation, sample preparation procedure, etc.

Ensure the quality of your products

Smart solutions and advanced management process data are key to optimizing your production and results.

Team

Shaping the

Foundry of the Future

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx