process data management

PDManager®- Digitalization, traceability and storage of foundry process data

Sistema de Control de la Producción en Tiempo Real para la digitalización, la trazabilidad y el almacenamiento ordenado de los parámetros clave que intervienen en el proceso de fabricación de los componentes fundidos.

Controla tu proceso de fundición.

Manage your process data, optimize your castings manufacturing process.

PDManager® is the Real Time Manufacturing Control System to digitize, correlate, treace and neatly storage the key parameters that intervene in the manufacturing process of metallic components within a centralized Database.

Composed by diverse modules, PDManager® makes it possible to control and manage the following aspects of production:

- Preparation of metal

- Preparation of molding sands

- Process of molding, in-line stay time and demolding

- Quality control applied to production

- Control plan management

- Management and tracking of indicences

- Query of stored information

Related contents

Advantages

Centralized and sorted process data

Storage of the relevant data in a single database, settling correlations among data and making it possible an intelligente interpretation.

Real time follow up of production process

Monitoring of the actual situation of the manufacturing at every moment and alert generation whenever some paramater divert from acceptable ranges.

A first step towards building an intelligent foundry

Improbement of process knowledge and control, as well as the quality of the production, thanks to the intelligent key data exploitation.

PDManager® modules

A modular system that fits your goals

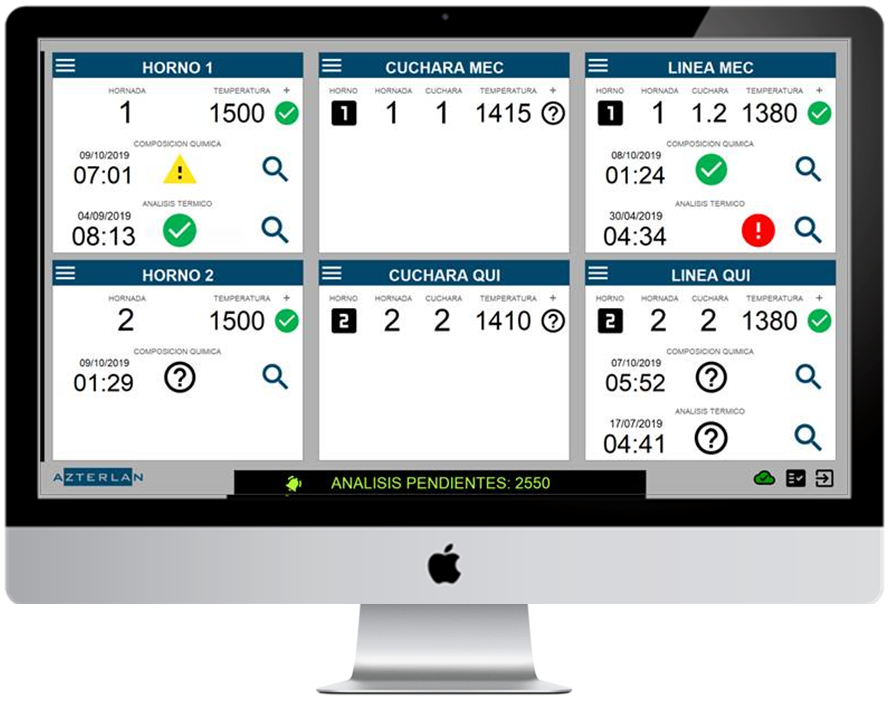

Melting & Pouring Module

Actual time, control and management of the preparation process of the metal.

Sand Process Module

Real time control and management of molding sands preparation process.

Moulding Process Module

Real time management of molding process, in-line stay time and demolding of each mold produced.

Product Quality Control

Real time management of quality control process applied to production. Applications for intermediaten controls and final inspection controls are included.

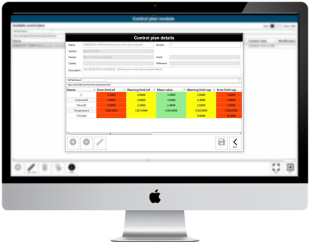

Control Plan Module

Activation of the control plan (specifications, acting limits and rejection limits) and reaction plan (alerts, corrective advice or requests for further controls).

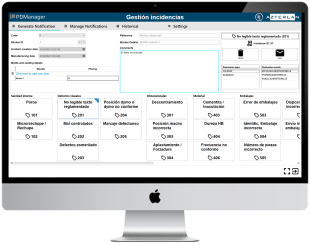

Notifications Module

Management and folllow up of the incidences, notifications and requests of internal operations generated in the plant.

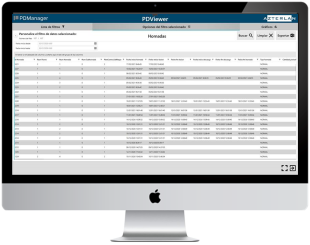

PDViewer Module

Access and query of the information stored in the central database. Applicaiton of filters, generation of graphs, exportable information for other softwares, etc.

Can I deploy PDManager® in my plant?

Get the best of your casting process

All iron foundries that store data from their manufacturing process (in any format) and believe that integrated data storage and intelligent data management can bring value to their process and their products can benefit from PDManager®.

Identification of the starting point

A simple diagnostic process allows to determine:

- data sources and formats of collection and storage.

- opportunities offered by the equipment and systems of the plant to provide and emit data.

- desirable data that is not yet captured..

Desing of data capture and storage system

- Definition of the data emission, capture and storage process.

- Installation of commercial sensors in relevant equipment that do not emit data.

- Data architecture design.

Related solutions

Control your manufacturing process

Contact our team if you think that a smart management of your manufacturing process can improve your results.

Team

Shaping the

Foundry of the Future

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx