LIFE REAMINE

Ongoing project

Innovation for a more sustainable foundry industry

The manufacture of foundry cores using the Cold-Box technique involves the use of aminated gases that activate the curing reaction of the resins used in the sand mixture. While this technique produces cores with high mechanical strength and dimensional accuracy, it also has a significant environmental impact due to the release of amines into the environment. These volatile organic compounds (VOCs) are highly irritating and toxic, harmful to human health. They also emit a strong, pungent odor.

For all these reasons, reducing amine emissions is among the objectives of developing more sustainable foundry processes, and the new Smitheries and Foundry BREF, published in December 2024, establishes a value eight times lower than the previous one (2.5 mg/m³N).

Innovative liquid amine recovery system

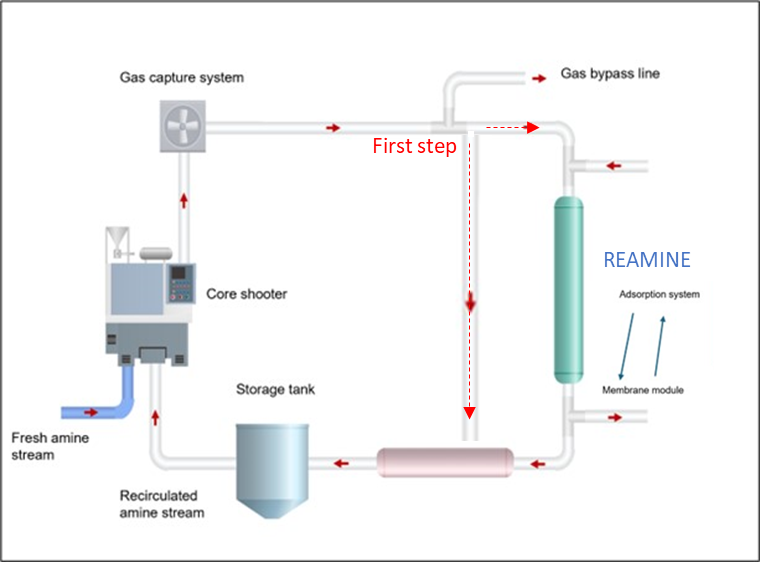

To address this problem, the LIFE REAMINE project seeks to develop, implement, and industrially validate the use of an advanced amine recovery technology in core manufacturing operations. The proposed solution will allow foundries to efficiently capture and recover liquid amines, thus facilitating their reincorporation into the core manufacturing process.

Technical coordinator

Related contents

Technological approach

The solution proposed by the LIFE REAMINE project integrates an adsorption column with a membrane device, creating an energy-efficient treatment system. This configuration effectively reduces amine emissions while facilitating the recovery of liquid amines. It will improve the efficiency of gas treatment, reduce cold box core manufacturing costs, and demonstrate its replicability across the entire foundry industry.

This solution will significantly reduce (>90%) amine emissions into the atmosphere (along with other NMVOCs).

The validation project will be installed in the core-making workshop of B1 production line at the BETSAIDE iron foundry facilities.

Project goals

The LIFE REAMINE project “SUSTAINABLE SOLUTIONS FOR NMVOC EMISSION REDUCTION IN FOUNDRIES THROUGH ADVANCED AMINE RECOVERY” aims to develop and validate an integrated, innovative, simple, cost-effective, sustainable, and replicable technology for collecting and recovering NMVOC emissions from the core manufacturing process using Cold-Box technology.

This innovative emissions reduction technology and the new approach to core production with regenerated catalyst will clearly support compliance with the latest standards established in the recent IED 2.0 and the new Smitheries and Foundry BREF document.

This development aims to contribute to the protection of environmental quality and human health by reducing industrial air emissions in the foundry sector and promoting resource efficiency through the capture and reuse of emitted amines.

Specific objectives

- Demonstrate the technical feasibility of the REAMINE integrated concept.

- Develop a prototype that is cost-effective, easy to maintain, easily automated, and durable.

- Integrate the project into general EU policies and promote a policy intervention plan to leverage specific funding lines in the Operational Programs.

- Monitor and evaluate the impact of the technology at an industrial scale and in different configurations.

- Reduce NMVOC emissions from the BET core manufacturing process by more than 13,860 kg and advance compliance with the current amine emission limit of 2.5 mg/m³ established in the new BREF document.

- Reduce worker exposure concentrations by 20% and ensure safe concentration levels in work areas (always below the OEL-TWA = 6.1 mg/m³).

- Reduce the impact of amine odor: 30% inside the foundry and >90% outside.

- Reduce annual amine consumption equaling recovery rate (90%).

- Ensure the replicability and transferability of the proposed technology and the dissemination of the EU results obtained by developing an adaptable and replicable solution in at least 78% of existing European foundries with serial production and cold box core manufacturing systems.

- Disseminate and communicate the results to users, customers, regional stakeholders, and the general public.

- Create a comprehensive implementation guide and training program to facilitate the adoption of this technology throughout the European foundry industry.

Main milestones

June 2025 – February 2027

- Define the REAMINE process baseline.

- Acquire the relevant process parameters to select the optimal REAMINE process configuration.

- Detail the REAMINE pilot plant flow diagram.

- Prepare the technical and administrative documentation required for the bidding processes prior to the demonstration plant design and construction of the REAMINE prototype.

- Obtain the necessary permits for the implementation of the REAMINE prototype from the relevant government (BASQUE GOVERNMENT).

- Build the REAMINE prototype and prepare for its integration into the Betsaide facilities.

March 2027 – May 2029

- Ensure the successful commissioning of the REAMINE prototype.

- Define an appropriate evaluation plan to assess the performance of the REAMINE solution.

- Optimize the REAMINE treatment train units in terms of the operating parameters of the membrane and adsorption units.

- Conduct long-term operational testing of the REAMINE solution in terms of performance, maintenance, energy, and reagent consumption.

- Adapt, demonstrate, and ensure the quality of cores manufactured using recovered amine.

June 2025 – May 2029

- Define, monitor, and report on project KPIs.

- Define, monitor, and report on the technical impact of the REAMINE solution.

- Evaluate the environmental impact of the LIFE REAMINE solution.

- Evaluate the socioeconomic impact of the project.

Expected impact

LIFE REAMINE will offer EU foundries a sustainable solution to reintroduce into their own production systems a compound (amine) that is currently emitted directly into the atmosphere or managed as hazardous waste after passing through a treatment system.

The overall potential impact of this solution extends to the majority (around 80%) of European serial production foundries, as well as other sectors with similar needs to which it can be transferred. These include the pharmaceutical industry, the agri-food industry, and the plastics manufacturing industry.

A scenario is proposed in which, within five years after project completion, 35 iron foundries will have integrated the REAMINE Solution, with the following estimated environmental, technical, and socioeconomic impacts.

Environmental Impact

- Reduction of 315,000 kg of amine emissions

- Reduction of emissions of other compounds such as phenol, formaldehyde, and isocyanates

- Improvement of the quality of the working environment for 2,600 people employed in European foundries (emissions and odors)

- Improvement of air quality affecting more than 1,271,000 citizens (emissions and odors)

- Reduction of 210,000 kg/year of amine emissions associated with ammonium salts

Technical Impact

- Recovery and reuse of 315,000 kg of amines

- Ensuring 95% amine purity

- Maintaining the core rejection rate below 2%

Socioeconomic Impact

- Promoting the incorporation of innovative technologies by foundries

- Fitting the solution with European policies and, therefore, funding calls

- Alignment of foundries with UN SDGs: SDG 8: Decent Work and Economic Growth; SDG 9: Industries, Innovation, and Infrastructure; and SDG 12: Responsible Consumption and Production.

Project consortium

News and dissemination

Funding

REAMINE is funded by the European Union’s LIFE programme under grant agreement LIFE-2024-SAP-ENV/101216139.

The content of this website is the sole responsibility of its authors and does not necessarily reflect the views of the European Union.