The most recent updates to the European environmental legislative framework have tightened the limits on amine emissions through gas evacuation systems. REAMINE technology will not only reduce amine emissions by more than 90%, as well as their impact on odors, but also allow for the reuse of this element in the core manufacturing process itself.

Due to its mechanical strength and dimensional accuracy, the Phenolic Urethane process, better known as Cold-Box, is the most widely used in the manufacture of foundry cores for long production runs. In this process, the binders used in the sand mixture are cured by amine gassing with a stream of compressed air. In this application, the amine acts as a curing catalyst, not being consumed. A small proportion of this amine remains retained in the manufactured core, and a significant portion of it is released along with the rest of the waste gas components through the extractio systems of the core making shopfloor. It is, therefore, a process with a high environmental impact.

As explained by researcher Andoni Ibarra, from the Sustainability and Environment research line of AZTERLAN, “the tertiary amines used in core shooters are volatile organic compounds (VOCs) that are habeing managed as hazardous waste after being chemically treated or incineration, these are costly processes that make it difficut for the industry to widespreadly incorporate them.”

The latest developments in European environmental legislation, defined by the Industrial Emissions Directive and the new Smitheries and Foundries BREF (in force since December 2024), have significantly tightened the limits for amine emissions permitted by foundry companies. In the case of the BREF, the new limit is <2.5 mg/Nm³, eight times lower than the previous version of the document (<20 mg/Nm³). Similarly, Directive 98/24/EC on the protection of the health and safety of workers from the risks related to chemical agents also identifies amines as hazardous chemicals and establishes limit values for amine concentrations in the workplace. “Amines have highly irritating and toxic properties, as well as a strong, penetrating odor, which is why occupational safety legislation also limits personnel exposure to them.”

Foundry cores manufacturing process

A hybrid solution to prevent emissions and recover and reuse amines

Faced with this problem, the LIFE REAMINE project consortium is focusing on developing an innovative technology based on adsorption technologies and the use of selective membranes to prevent amines from being released into the atmosphere and, at the same time, allow them to be recovered for reuse in the core manufacturing process at the same foundry. “Our approach to the REAMINE solution is completely practical and aligned with industrial priorities and needs: we are working to develop an effective, economically viable, and systematically deployable system in different foundries, allowing them to comply with environmental legislation and improve their working environments without affecting the quality of their products. We will also work to ensure that the developed innovation is classified as BAT and, once the development prototype is finalized and validated, it is eligible for public funding programs.”

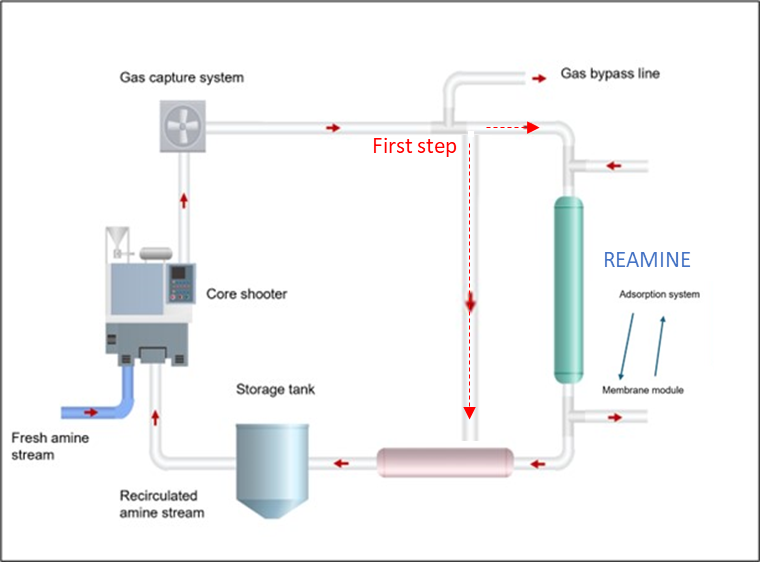

From a technological perspective, the REAMINE solution consists of a hybrid system that integrates an adsorption column with a membrane device, creating an energy-efficient treatment system. This configuration effectively reduces amine emissions while facilitating the recovery of amines in liquid form. As a result, these recovered amines can be reincorporated into the core manufacturing process. They will thus contribute to improving the efficiency of gas treatment and reducing core manufacturing costs using Cold-Box. “The purity and recovery rate targets we aim to achieve with this technology are >95% and >90%, respectively. This will be the savings foundries will generate in the purchase of this element and, of course, will contribute to reducing the environmental impact associated with its production and transportation. These are significant figures considering that an average foundry process can consume and emit more than 10,000 kg of amines per year.”

As a project demonstrator, an industrial prototype will be implemented and validated and installed in the core manufacturing area of the Betsaide iron foundry (Elorrio, Bizkaia).

Scheme of the REAMINE Solution to be developed to recover amines in liquid state

Supporting foundries in their transformation and maintaining their position among the manufacturing technologies of the future

Process industries are undoubtedly in Europe’s spotlight due to their significant emissions and waste generation, as well as their high energy consumption. However, they remain one of the main economic drivers of EU countries. In the case of iron foundry, the European castings industry is the third largest in the world in terms of volume after China and India, and is responsible for 15% of global production of cast iron components.

“Foundry is an important driver of the economy and employment in our immediate surroundings, and it is in our hands to ensure that it continues to be a driving force of wealth and technological and social development. We have no doubt that foundry will continue to play a fundamental role among the manufacturing technologies of the future, and at AZTERLAN, as a technology center specializing in metallurgy, we have the clear mission of supporting foundries in their constant evolution, supporting them in their efforts to remain aligned with the values and needs of current and future society. We believe that innovations like the one we are addressing in LIFE REAMINE are a good example of this.”

The LIFE REAMINE consortium is led by AZTERLAN and includes the participation of the companies BETSAIDE, S.A.L. and APRIA Systems, the innovation agents NOVA School of Science and Technology (University of Lisbon) and the University of Cantabria, and the Association of Foundries of the Basque Country and Navarre (FEAF). This research project is funded by the European Union’s LIFE programme under collaboration agreement No. LIFE-2024-SAP-ENV/101216139.