ALUMINUM FOUNDRY

Reduces cycle times, sound castings and improved mold life.

Azterlan’s ALU-C® methodology designs, models, and manufactures mold inserts with embedded sensing that significantly advance the current state of the art in HPDC.

By combining advanced thermal engineering with additive manufacturing and sensoring strategy, ALU-C® delivers a breakthrough solution: a design based on an optimized thermal map of the mold to maximize overall process efficiency for HPDC, LPDC & GDC.

- Improved product quality and lower scrap rates by reducing thermal defects.

- Reduced cycle time through faster and more controlled heat dissipation.

- Increased lifetime of inserts, sensors, and thermal components.

Related contents

Advantages

EXTENDED MOLD LIFE

Simulation-driven optimized designs and real-time monitoring with embedded sensors to detect anomalies during operation.

CYCLE TIME OPTIMIZATION

Reduction of the solidification time of the die-cast component through enhanced heat transfer between the ALU-C® insert and the aluminum.

SOUND CASTINGS

A higher solidification rate generates a finer microstructure in the castings, leading to potential improvements in their mechanical properties. In addition, ALU-C® also reduces the risk of shrinkage-related defects.

OUR METHODOLOGY

Leveraging Thermal Management for

Die-Casting Process Efficiency

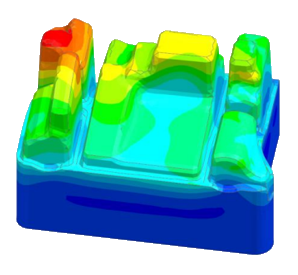

1. In-Depth Thermal Study

Detailed analysis of the mold’s heat flow, identifying hotspots, cooling constraints, and thermal imbalances to define the optimal thermal strategy for maximum stability and performance.

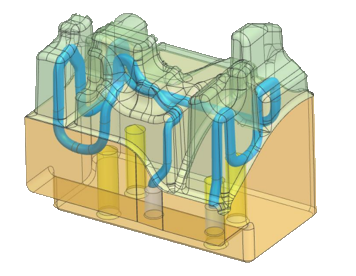

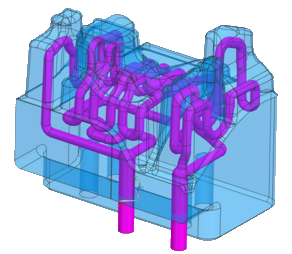

2. Insert-Based Mold Architecture

Mold-design as a set of specialized inserts, each incorporating a tailored thermal-management geometry. Thanks to additive manufacturing, cooling channels and material transitions can be fully optimized for the specific operating environment.

3. Engineered Cooling® & Thermal Monitoring

Integration and protection of sensors within the inserts to generate precise real-time thermal data.

Development of systems that introduce thermal-management strategies into the mold (AZTERLAN’s engineered cooling® methodology), ensuring the mold reaches the desired transients and remains thermally stable throughout the cycle.

Manufacture injected components with optimized properties

Contact our team if you think we can help you optimize any aspecto of your manufacturing process.

Team

Shaping the

Foundry of the Future

“The Foundry of the Future is that of connected processes that is able to take advantage of the knowledge generated inside the company at the same time that it keeps learning from its manufacturing and market experience.

Along with a deep knowledge of metallurgy, Industry 4.0 technologies, advanced data management systems and machine learning technologies have landed in this industry to transform the way castings are conceived”.

xxxxx