In its final phase, the CIRCOM research team is developing pilot tests that will validate the performance obtained with each of the new materials developed in a relevant environment.

Using alkaline activation technology for industrial waste generated in both the metal sector (steel slag) and the construction sector (construction and demolition waste or CDW), the CIRCOM project consortium has managed to develop and optimize new recycled cementitious products with improved performance:

- Cement and resin-free material for the manufacture of casting molds, based on a binder-sand system manufactured entirely from the recovery and conditioning of black slag.

- Refractory cement-free concrete with high mechanical and thermal resistance, obtained through the alkaline activation of black slag.

- Sustainable mortar based on the valorisation of CDW, from an optimised alkaline activation procedure on the useful fractions of said waste.

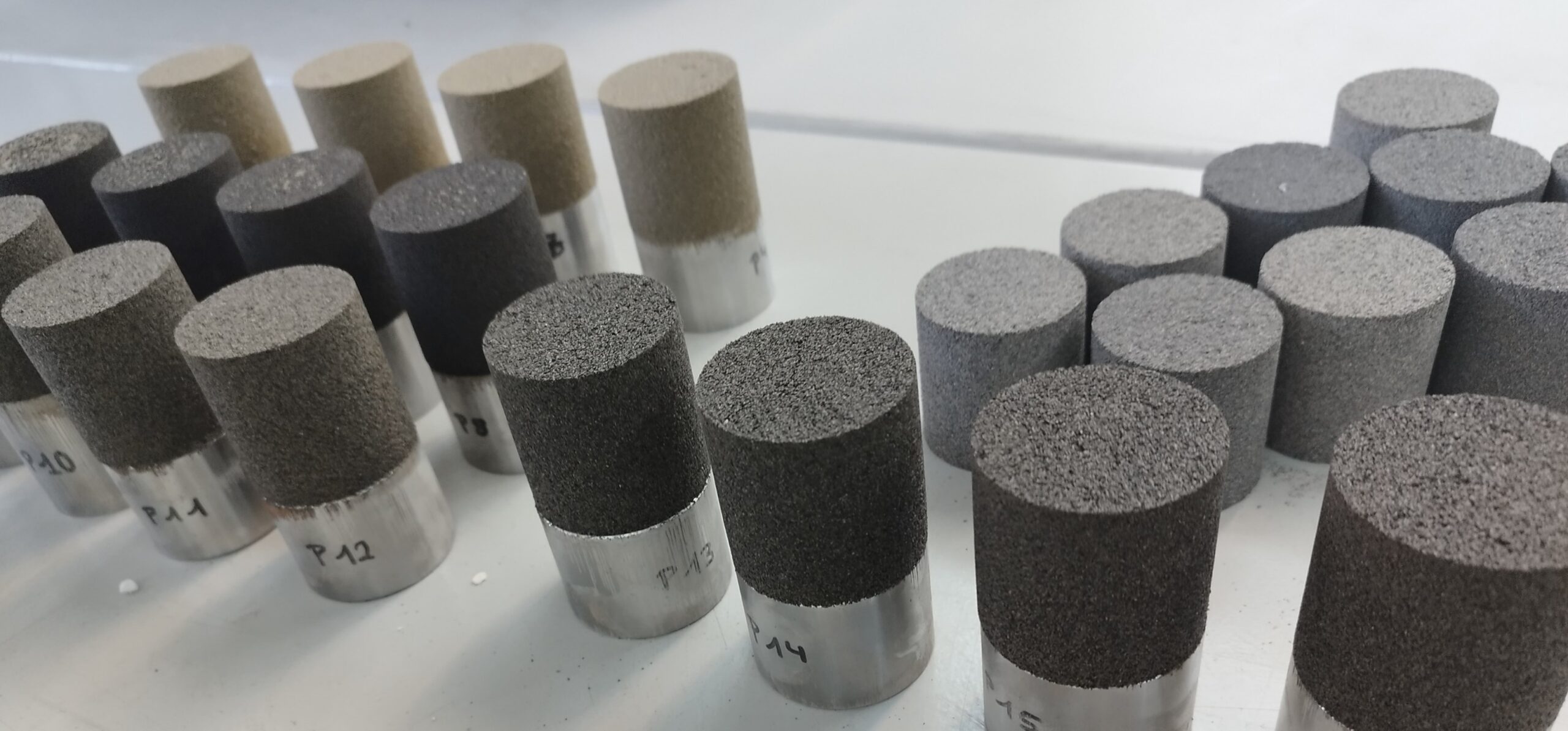

After validating them on a laboratory scale, the research team is currently developing pilot tests that will allow the validation of the performance obtained from each material in a relevant environment.

Samples for analysis of new recycled materials with cement characteristics developed in the CIRCOM project

Revalorisation of industrial waste for use in new applications

Alkaline-activated materials (AAM) function as binders by the reaction of an alkaline metal source with a solid precursor. When the reaction occurs, the material sets and hardens, developing a compound with cementing properties similar (even improved) to those of ordinary Portland cement.

The CIRCOM project has focused on addressing a double environmental need within the metallurgical and construction sectors: the search for cementitious materials that allow the physical, chemical and mechanical properties of current cements to be improved, and the development of solutions to conserve non-renewable resources by generating raw materials that improve production processes and the quality of the final products.

With these objectives, in a first phase, the work team focused on defining the most suitable selection and collection process for waste, as well as its analysis using different physical-chemical characterization methods and its conditioning to achieve the most suitable particle size and homogeneity for the target performance of the final products.

Subsequently, the project’s activity was mainly oriented towards the design of binder formulations to obtain binders with optimal properties for each of the proposed applications. In the final phase of the project, the team is working on validating these developments using application demonstrators in relevant environments.

The CIRCOM Consortium has met on several occasions throughout 2024.

CIRCOM has a multidisciplinary and cooperative consortium made up of the companies REINOSA FORGING & CASTINGS, S.L., coordinator of the project, and CANTERA LA TORRETA, S.A., and the Technology Centers AIMEN, ITC-AICE and AZTERLAN.

The CIRCOM project with reference CPP2021-008798 is funded by MCIN/AEI/10.13039/501100011033 and by the European Union-NextGenerationEU/PRTR