New materials

Development of new high-performance materials.

Powder metal is a booming market niche, especially in new additive manufacturing processes that are added to more conventional powder metallurgical processes, such as sintering or compacting.

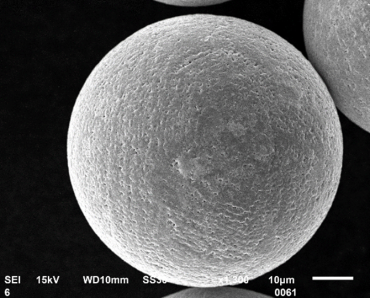

From its metallurgical expertise, AZTERLAN reinforces its activity in the field of the development of new materials through the development of ad-hoc metal powders (composition, particle size, high-spheroidity) through all stages from conception to application, until reaching the final component. The design of the new powder alloys is aimed at maximizing the performance of the material during its atomization, deposition, heat treatment and subsequent finishing processes.

The combination of Ultrasonic Metal Powder Atomization capabilities with melting and liquid metal treatment capabilities allows AZTERLAN to manufacture modified alloys in graduated chemical compositions in an agile manner.

Main features

CONCEPTION AND MANUFACTURE OF AD-HOC METALLIC POWDER

Processing of all types of materials

Applicable for the manufacture of powders of all types of metallic materials, reactive or non-reactive.

The main materials to be sprayed include, among others, materials with special properties such as superalloys (nickel base), high entropy alloys, titanium, magnesium, precious metals or refractory metals, as well as aluminum

Versatility of raw materials and customized compositions

Possibility of creating metal powders from bars, thread and metal chips.

Together with AZTERLAN’s alloy manufacturing capabilities, it is possible to develop ad-hoc materials in a format compatible with powder atomization capabilities for subsequent atomization.

Manufacture of "master alloys" in powder format

Manufacture of powders doped with the selected alloying elements that can be used as “mother alloys” and, by mixing them with commercial powders, give rise to an ad-hoc metallic powder with graduated chemical compositions depending on the mixture.

Development of the additive from the material

Design and development of alloys and optimized particle shape and size for each specific additive manufacturing process (laser cladding, SLM, binder jetting, EB-PBF, L-DED, FDM, L-PBF) taking into account the effect of the parameters of the additive process in the metallurgical transformations of atomized powders and also optimizing the post-processes of hardening and improvement by thermal treatments.

Speed, security and response capacity

The ultrasonic method allows solving the safety and oxidation problems implicit in the handling of reactive alloys in powder format.

It also offers a short lead time, speed in changing materials, versatility in terms of quantities to be manufactured and performance of over 95%.

Main applications

DEVELOPMENT OF ADDITIVE MANUFACTURING THROUGH MATERIAL

1) Advanced coatings

The application of metal powders of advanced materials on the surface of the components using different additive manufacturing techniques makes it possible to provide the components with advanced characteristics such as greater resistance to wear, corrosion or thermal fatigue.

2) Development of multi-material components

Thanks to additive manufacturing technologies and the design of ad-hoc metal powders, it is possible to create multi-material components in which different areas of the component, subjected to different loads and environments, are composed of the most suitable material for optimal performance.

3) Convergence and hybridization of manufacturing technologies

The combination of metal powder technologies with other manufacturing means (casting, forging, stamping, lamination, etc.) is a fundamental area of work to advance the design of complex geometries and promote manufacturing flexibility in terms of times. as costs.

AZTERLAN capacities

FACILITIES AND EQUIPMENT DEDICATED TO THE ATOMIZATION AND CHARACTERIZATION OF METALLIC POWDER

AZTERLAN has the most advanced equipment and facilities dedicated to the development and characterization of high-performance metal powders:

- ATO Lab Plus equipment for the atomization of powders from bars, metal wire or machining chips.

- Particle size: 20-120 microns, with the possibility of supplying limited ranges by sieving

- Production capacity: from 20 gr. to several kg.

- Characterization of metallic powders: Histogram, Fluidity, Spheroidity, Humidity.

- Argon protected atmosphere.

Advanced components

We can help you manufacture components with advanced properties.

re·Thinking Metallurgy

“Nuestra labor se orienta a dominar la física y la química que gobiernan el comportamiento de las aleaciones metálicas, los fenómenos que tienen lugar durante los procesos de fabricación y los condicionantes que afectan a la vida útil de los componentes metálicos.

Repensamos la metalurgia y desde la metalurgia para desarrollar procesos de fabricación más eficaces, eficientes y sostenibles que favorezcan la fabricación de componentes con propiedades avanzados y que permitan abrir nuevos campos de aplicación.”